Competence with tradition

The history of our company is marked by tradition and rapid progress. The company's foundation stone was laid in the Middle Ages. At the close of the 1980s a speedy development started which turned a medium-sized German company into a multi national group within less than a decade. The most important stops on our way to become a global player can be viewed here.

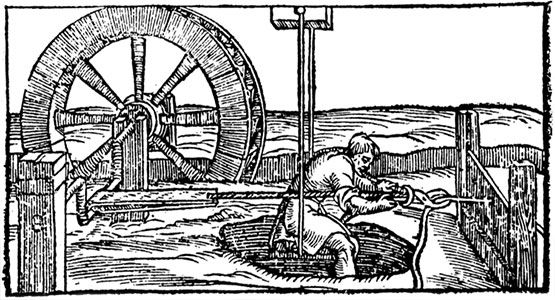

The LEONI story from the very beginning

1621

Fournier's sons established other workshops for the manufacture of Lyonese Wares south of Nuremberg, including one in Roth

This gave rise to several other companies

- Johann Balthasar Stieber & Sohn, Nuremberg

- Johann Philipp Stieber, Roth and

- Vereinigte Leonische Fabriken, Nuremberg

1989

LEONI commence acquisition strategy with takeover of Westfälische Kupfer- und Messingwerke AG, Luedenscheid, Germany (production of wires and strands) and Kabelfabrik Otto Zimmermann (OZET), Lilienthal, Germany (production of cables and cable harnesses)

1996

Takeover of Temco Ltd. Stanford, England (wires and stranded conductors) Takeover of EPAN shares and change of name from EPAN-LEONI to Leonische of Asia, Singapore

1997

Takeover of wiring harness business activities of Cummins Engine Company Inc., Columbus, USA and integrating it into LEONI Wiring Systems Inc., Tucson (formerly LEONI Cable Assemblies Inc.) Foundation of Leoni Cable Mexico, Hermosillo Foundation of LKH, Leonische Kabelwerke Kft. Hatvan, Hungary (cable production)

1998

Integration of the company OZET Lilienthal, Germany (cable harnesses) into Leonische Drahtwerke AG; merging of the subsidiaries CDC and CDS Tunisia to Leonische Tunisie (cable harnesses); takeover of the companies CWA, Belgium, now LEONI Cable Assemblies (Belgium) N.V. (cord sets) and elocab, Georgensgmünd, Germany (special cables); foundation of LEONI Wiring Systems (East London) in South Africa (cable harnesses) and LEONI Cable Inc., Mexico (cable)

1999

Acquistion of what is now LEONI Special Cables GmbH, Friesoythe, Germany (special cables), LEONI Automotive Leads GmbH & Co. KG (cable assemblies), and LEONI Kablo ve Teknolojileri, Gemlik/Bursa, Turkey (cable). Establishment of a holding structure: Leonische Drahtwerke AG change the company’s name to LEONI AG and solely function as a holding company. Three companies run the strategic business: LEONI Draht GmbH & Co. KG, LEONI Kabel GmbH & Co. KG, LEONI Bordnetz-Systeme GmbH & Co. KG

2000

Takeover of the American TRW group’s business activities; new trading name LEONI Wiring Systems UK, Newcastle-under-Lyme, England.

Establishment of LEONI Cable Slovakia spol. s.r.o, Stará Turá (Slovakia); production programme: cable assemblies and car kits for mobile phones. Set-up of LEONI Draht Polska Sp. z o. o., Kobierzyce (Production programme: wires and strands for cable production) and LEONI Kabel Polska Sp. z o. o., Kobierzyce (automotive wires), both in Poland.

The LEONI Kabel GmbH & Co. KG plant in Roth together with the cable plants in Friesoythe and Brake are certified according to the ISO 14001 environmental standard Official opening of the new cable plant LEONI Cable S.A. de C.V. in Cuauthémoc, Mexico.

LEONI Kabel GmbH & Co. KG take on 51 % share of Protec Kabel Produktion GmbH, Schmalkalden, Germany; takeover of Protec Kabel GmbH, Bretzfeld, Germany. Protec is a manufacturer of ready-to-install tailor-made cables and cable systems e.g. for industrial robots.

2001

LEONI Bordnetz-Systeme GmbH & Co. KG awarded as Best Supplier of the Year by Porsche AG Joint venture of LEONI Bordnetz-Systeme GmbH & Co. KG and Hella KG Hueck & Co to form Intedis GmbH, Wuerzburg, Germany, for the development of intelligent wiring systems LEONI subsidiary Elocab Sonderkabel, Georgensgmuend, Germany, take over French enterprise Composants Industriels Automobiles (CIA), producer of cable systems for robotics

2002

Ernst Thoma, for 25 years Chairman of the LEONI AG Management Board, appointed to Chairman of the Supervisory Board. Dr. Klaus Probst succeeds as new Chairman of the Management Board LEONI AG, previously listed on the SDAX, admitted to the MDAX stock index LEONI Kabel GmbH & Co. KG acquire a majority holding in FO-Systems GmbH, Neuhaus-Schierschnitz, Germany, specialist in the field of fiber optic cables.

2003

Official opening of two new LEONI plants in China: LEONI Special Cables (Changzhou) Co. Ltd., producing special cables, and LEONI Wire (Changzhou) Co. Ltd., producing wire and stranded conductors. LEONI one of the first companies in the world to issue a “Declaration on Social Rights and Industrial Relations”, short “Social Charter”. In the Ukrainian city of Stryi the so far biggest LEONI plant ever built will be inaugurated as well as the second Romanian wiring systems site in Bistrita which has been erected in record time. Both plants produce cable harnesses for the automotive industry.

2004

In two separate production areas covering a total area of 25,000 m2, series production of cable harnesses starts at the new facility in Bistrita, Romania LEONI acquire the Ettlingen, Germany based company Klink+Oechsle, special cable assembly The activities of LEONI Group in the field of fiber optics are consolidated in LEONI Fiber Optics GmbH, Germany Series production of customised cable harnesses for BMW’s new 3 Series starts at the new facility in Ilava, Slovakia with about 18,000 m2 of space.

2005

LEONI acquire neumatic Elektronik + Kabeltechnik of Ulm, Germany, a business specializing in tailor-made cable harnesses and dedicated electronic solutions.

LEONI acquire all the shares in the Stolberg-based data and special cable manufacturer KERPEN and thereby become Germany’s leading provider of cables and cabling systems for data transmission.

LEONI & STUDER Transportation Systems, a joint venture with the Swiss cable manufacturer Studer, commence operations (rolling stock).

2006

LEONI awarded for the 3rd time in a row as one of the top employers in Germany by the Corporate Research Foundation. Vital categories are good working conditions, social benefits and career development opportunities for employees.

LEONI earn fourth “Supplier of the year” award from General Motors as worldwide best wiring systems partner.

LEONI set up new facility In North-Rhine Westphalia with LEONI High Temp Solutions for the production of high temperature cables.

LEONI acquire the Austrian systems company NBG Fiber-Optics to strengthen the optical glass fiber business LEONI acquire majority stake of j-fiber GmbH, based in Jena, Germany.

2007

The newly-introduced “Code of Ethics” is a code of behavior that commits everyone who works at LEONI to responsible and integrated action. It defines globally uniform values and requirements. The code is based on statutory regulations and stipulates among other things that information must be handled sensitively as well as prohibiting corruption and discrimination.

With its controlling interest in FiberTech, the Wire & Cable Solutions division is systematically tapping a further market niche with above-average profit potential. FiberTech specializes in the production of high-quality glass fibers and complete fiber optic systems for laser beam transmission, a technology used, for example, in medical technology.

2008

LEONI acquires the wiring harness division of the French automotive supplier Valeo at the start of the year, thereby realizing the most important acquisition in the company’s history. Together with the renamed LEONI Wiring Systems France group, LEONI becomes the European market leader and fourth-biggest supplier of wiring systems for the automotive industry in the world.

With the cabling of the Gotthard Base Tunnel, the company receives a major contract for energy supply and safety cables for the longest rail tunnel in the world.

LEONI taps the vehicle market in Korea with its share in the wiring manufacturer Daekyeung.

2009

Furthermore, LEONI receives the Porsche Supplier Award for the fifth time, with which the sports carmaker commends the quality, flexibility, efficiency and customer service of its best suppliers.

LEONI Wiring Systems wins a first contract to supply wiring systems for the Nissan X-Trail from Japan.

At a price of € 14.50 per share, LEONI sells 2.9 million treasury shares that the Company purchased at an average price of € 9.79 under a buy-back program in 2008. LEONI thereby strengthened its equity base and reduced its net debt.

2010

LEONI expanded due to the good forecasts for the Asian market. The expansion started at the beginning of the year with the opening of a base in Nagoya, thereby pooling the activity of our Wire & Cable Solutions Division in Japan. In the spring added a development office in Pune, India was added for LEONI’s wiring systems operations.

With the aim of broadening its position on the international commercial vehicle market further, LEONI took over the production plant of an AEES Power Systems Group factory in Beiuş, north-western Romania and thereby gained additional business.

Following extensive preparatory work, LEONI started in June by delivering the first 350 kilometers of power cable for the Gotthard Base Tunnel in Switzerland.

With its acquisition of the US-based optical fiber technology specialist RoMack Inc., LEONI further strengthened its position in the fiber optics growth market on the American continent.

Siemens Mobility commissioned LEONI to supply all the cabling for its ICE (Inter-city Express) successor Velaro D, which started operating on Deutsche Bahn’s rail network in 2011.

2011

The mia microbus, to be launched on the German and French markets, is the first electric vehicle to be fitted as standard in both the low voltage and high voltage domains with a complete wiring system from LEONI's Business Unit Electromobility.

LEONI joined the UN Global Compact. The Company thus committed itself to more sustainability and will report annually on corresponding progress. It also announced that it would bring forward its takeover in full of the Korean wiring system manufacturer Daekyeung to 1 January 2012. In addition, LEONI Wiring Systems opened another production facility in China. Initially, about 1,600 employees in Jining will, on a space of more than 25,000 square metres, produce wiring systems for the Chinese car market.

2012

LEONI opened a sales office in Dubai with an initial focus on high-quality cabling systems for infrastructure projects. A cable production facility was also commissioned in the Pune District to utilize the opportunities offered by the Indian market.

LEONI formed the new Business Unit Connectivity within the Wiring Systems Division to improve LEONI’s competence in connectors and plug connection systems.

2013

In April, not one but two awards confirmed the strong position enjoyed by LEONI’s Wiring Systems Division in the growth market China. First, the Benz Beijing Automotive Company (BBAC) selected LEONI as one of their most important suppliers and second, the trade publisher “Vogel Industry Media China” commended LEONI as one of the TOP 50 automobile suppliers in China.

The opening of a new plant near Pune to supply standard cables for the rapidly growing Indian automotive industry further increased the Wire & Cable Solutions Division’s international outlook.

The Wiring Systems Division opened a fourth wiring system plant in China.

LEONI’s goal of manufacturing and supplying products to the same high level around the world was achieved in November 2013. LEONI’s position in the American passenger vehicle market was consolidated as pre-production of wiring systems for the new Mercedes C-class began.

2014

In February LEONI obtained a major order from the petrochemical industry: the Indian producer Reliance Industries commissioned LEONI to provide the wiring for the world’s largest oil and gas refinery.

Siemens Healthcare commended the outstanding performance of LEONI’s Business Unit Healthcare by bestowing us its Supplier of the Year award for what was the second time already. PSA Peugeot Citroen also praised LEONI’s very high standard of quality and presented our wiring systems facility in Itú, Brazil with its Supplier Award in the quality category.

The Swedish truck manufacturer Scania ordered cable harnesses from LEONI for several engine models that will be supplied across Europe and in Brazil. LEONI now has all major European truck manufacturers among its commercial vehicle customer base.

In the Investors’ Darling 2014 competition run by Manager magazine, LEONI took first place among the mid-cap companies of the MDAX index. Annual and interim reports as well as websites and presentations for investors were drawn upon as criteria for the best capital market communication in Germany.

2015

In January, LEONI received the first cable system order from Hyundai Motor Company.

On 7 May 2015, Dieter Bellé became the President & CEO of LEONI AG. As CFO and Labour Director, the 60 year-old has been a board member since 2000. Now he assumes the role of chairman in addition to his previous duties.

LEONI is opening its fifth plant in China for vehicle wiring systems. Since January 2016, production and development has been under way in Tieling, in the north of the country, for the supply of products to the new customer BMW Brilliance Automotive.

In November the first vehicle wiring system factory will open in Paraguay. The new facility in San Lorenzo near the capital city Asuncion will manufacture cable systems for customers from the automotive and commercial vehicle industry with production locations in Argentina and Brazil.

2016

In February a team of international researchers succeeded in recording the collision of two black holes based on their gravitational waves and therefore metrologically proving Albert Einstein’s general theory of relativity – assembled LEONI fiber optic cables are fitted in the gravitational wave detectors used for measuring.

The advintec 6D laser measurement calibration system was praised as one of the most innovative exhibits at the Automatica trade fair in June.

In September LEONI acquired a 51 percent stake in the Chinese wiring systems manufacturer Wuhan Hengtong Automotive. Wuhan Hengtong will initially supply the carmaker DPCA, a joint venture between the PSA Group and Dongfeng, China’s second largest motor vehicle manufacturer.

New construction in Ukraine: In October the Wiring Systems Division laid the foundations for a new plant in Kolomyia, western Ukraine. This second facility in the country is set up for approximately 5,000 employees and is to produce wiring systems for the European automotive industry from 2017.

2017

LEONI demonstrated its diversity and showed that tradition and progress go together during its anniversary year. Festivities, videos, promotional and PR activity as well as interactive schemes for staff brought the Company's history to life: from the wire works established in 1917 through to becoming a specialist for intelligent energy and data solutions.

In February, LEONI acquired two-thirds of Zurich-based Adaptricity AG, which specializes in software-supported consulting services. With this Swiss start-up business, the Wire & Cable Solutions Division (WCS) gained additional know-how in the areas of software, simulation and cloud-based data analysis.

Construction of the Factory of the Future, which will combine state-of-the-art cable production with a high-tech laboratory and development center for innovative products and solutions, started in Roth, Germany.

LEONI opened its second plant for cable harnesses and wiring systems at its new location in Kolomyia, western Ukraine. With its third wiring systems facility in Mérida, Mexico, which will make an important contribution to an environmentally friendly production site with a solar power plant and a water recovery system, the Company also expanded its capacity in the Americas.

2018

With the Supervisory Board’s understanding, Dieter Bellé resigned his mandate as member and chairman of the Executive Board effective 31 January 2018 and left the Board at that time.

LEONI presented its LEONiQ key technology – an intelligent cable technology that can record and evaluate such parameters as temperature and mechanical stress along any given cable system.

In the city of Niṧ, LEONI officially opened its third wiring systems plant in Serbia. On a production space of approx. 20,000 m², the plant will make cable harnesses for one of the global manufacturers of premium vehicles. LEONI is investing about € 22 million in the production facility, which will create about 2,200 jobs by the end of 2019.

Aldo Kamper, an internationally experienced executive, took over as chairman of LEONI’s Executive Board. The Dutchman, who was previously CEO of Osram Opto Semiconductors, is commercially and technologically minded in equal measure.

With VALUE 21, LEONI initiated a comprehensive and long-lasting strategy and performance enhancement program. The objective is to sharpen the future corporate strategy, direct the Company towards healthy growth and improve both earnings quality and liquidity.

2019

LEONI and Hengtong, a provider acting globally of cables and system solutions for the telecommunications and energy sectors, establish joint venture for singlemode fibers.

IPO or sale of Wire & Cable Solutions Division planned, in order to create two entities. LEONI will in the future concentrate on the wiring systems business, the WCS Division will get more independence.

The first LEONI staff move into our Factory of the Future in Roth, Germany whose new center of expertise is to develop and produce state-of-the-art data cables for autonomous driving.

LEONI starts series production of wiring systems for the ID.3, Volkswagen’s first car to be designed as a purely electric vehicle.

2020

The spread of the COVID-19 virus in March resulted in major carmakers stopping their production. Against the backdrop of the related sales decline involving numerous customers and products, LEONI was also forced to decide to temporarily but sharply curtail production at its European, North African and American wiring systems facilities.

LEONI presents its first active fiber optic and copper cables that can transfer data volumes of 400 G/s and more that are well suited for the challenges of growing data transfer rates driven by megatrends such as big data, 5G, IoT (Internet of Things) and artificial intelligence.

As the world’s first cable manufacturer, LEONI launched Single Pair Ethernet (SPE) data transmission technology cables for use in drag chains and torsion applications.

2021

Extensive ramp-up of production of wiring systems for vehicles based on the Volkswagen Group’s modular electric drive matrix (MEB) picked up pace at several LEONI facilities.

By selling Studer AG and the LEONI Schweiz AG umbrella company, LEONI took a major step towards focusing on the wiring systems business.

Furthermore, the Data Communication and Compound business units belonging to LEONI Kerpen GmbH in Stolberg were sold via a management buy-out.

The Center of Automotive Management (CAM) and PwC consulting firm commended LEONI with the AutomotiveINNOVATIONS Award 2021. LEONI won this prestigious award in the ‘Interior and Interface’ category for an ACC cable that facilitates super-fast data transfer in a high bandwidth.

LEONI opens new plant in Kraljevo, Serbia, creating 5000 jobs and advancing to being the country’s largest private-sector industrial employer.

LEONI continued its strategic focus on the wiring systems business by agreeing to sell the LEONI Fiber Optics companies and j-plasma GmbH.

2022

Start of the performance and strategy program ValuePlus after the successful completion of VALUE 21. With ValuePlus, LEONI is further enhancing its business model in order to better utilize the opportunities on the automotive and commercial vehicles industry’s market.

Outbreak of the war in Ukraine. Thanks to the team-spirit within the LEONI-family and the outstanding commitment of the employees at both Ukrainian LEONI-locations, , the effects will be mastered in the best possible way in the following months. After a brief disruption, production in Ukraine can be resumed again quickly.

Dr Ursula Biernert as CHRO, Ingo Spengler as COO and Dr Harald Nippel as the new CFO join the Board of Directors.

Climate-neutral by 2045: LEONI launches its sustainability program ReWire.

Opening of the Innovation Industrialization Center (IIC) at our location in Kitzingen, Germany. In this think-tank for the wiring system of the future, new wiring system-architecture for the mobility of tomorrow is being developed.

The sale of the Business Group Automotive Cable Solutions was refused by the buyer. LEONI immediately started to adjust the refinancing as well as the restructuring concept to the new situation in collaboration with the creditors. Credit lines due at the end of the year are being temporarily prolonged.