System Integrated Solutions

Complete solutions for wiring systems

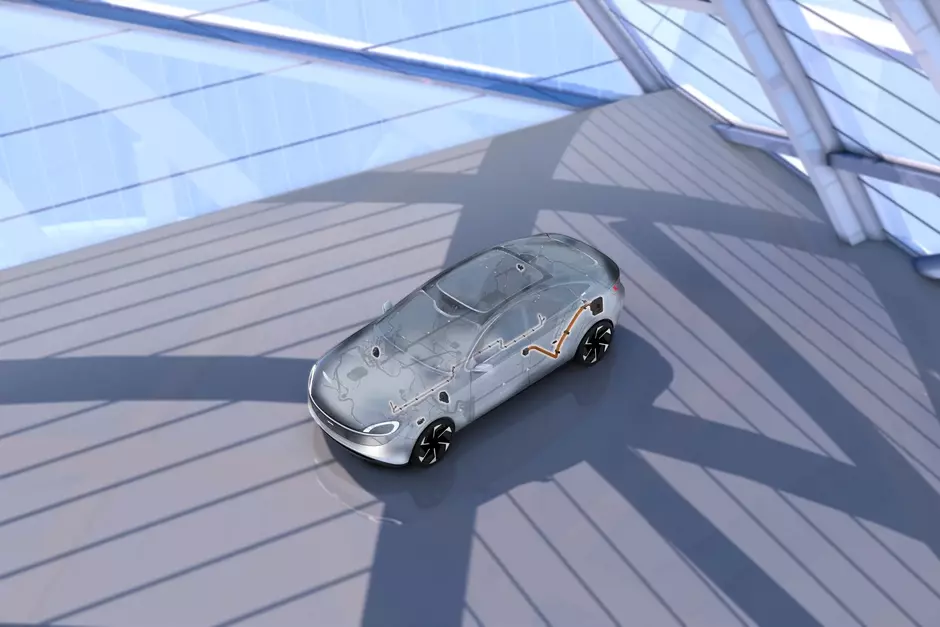

We offer our customers complete solutions for cabling systems - from the entire wiring harness to the full integration of the necessary add-on parts - in order to implement customer- and architecture-specific data and power distribution in the vehicle in the best possible way. We are always on the lookout for even more efficient, innovative and cost-optimized solutions - to make our overall solution even more attractive for our customers.

Our products

In recent years, a trend has emerged on the market whereby conventional, flexible round conductors are increasingly being replaced by rigid busbars. So-called busbars are used in the low-voltage sector, for example the power busbar, as well as in the high-voltage sector as module connectors and in the form of the charging busbar, which represents the charging path. The rigid, flat or round geometry enables largely automated processing and handling. The available, usually limited installation space can be used in the best possible way thanks to the flexible and individual realization of bends. The increased surface area ensures optimized heat dissipation. The use of aluminum instead of copper enables weight and cost savings to be achieved. LEONI has comprehensive system integration expertise based on specific customer and architectural requirements, making it the right partner from design and development through to global production.

The facts at a glance:

- Rigid, flat or round geometry enables automated machining and handling

- Optimized heat dissipation due to increased surface area

- Change of material from copper to aluminum enables weight and cost reduction

Automotive data cables are essential components of today's vehicles, connecting data and control signals between various electronic components. They are used in a variety of applications, including powertrain systems, advanced driver assistance systems (ADAS), infotainment systems and charging systems for electric vehicles.

The data cables are usually integrated into the low-voltage electrical system. Shielded, twisted special cables with different cross-sections are used for this purpose. In addition, special connection systems provide protection, shielding and, in some cases, sealing of connections. The cables are particularly sensitive to bending, as this can impair data shielding and signal integrity. Data cables are an important key product for intelligent vehicles and Drive-x-Wire functionality.

The facts at a glance:

- Use of shielded, twisted special cables with different cross-sections

- Special connection systems that enable the protection, shielding and, in some cases, sealing of connections

- High sensitivity to bending, as data shielding and signal integrity can be compromised

- A key product for intelligent vehicles and Drive-x-Wire functionality

Harness attached parts include products that are attached directly to the wiring harness, such as grommets, cable ducts or plastic and metal brackets.

Cable ducts, which are optimized for installation space and weight, together with brackets ensure that the wiring harness is routed safely and securely in the vehicle. Recycled materials are used here to minimize the CO2 footprint. Grommets and seals ensure reliable protection against the ingress of media, especially water, as well as a high level of acoustic damping of external noise inside the vehicle. Depending on the application, different methods can be used to achieve the optimum solution. Foam grommets, for example, are particularly suitable for targeted cable routing in tight installation spaces.

The facts at a glance:

- Foam grommets integrated in wiring harnesses

- Assembly-optimized grommets, partially patented

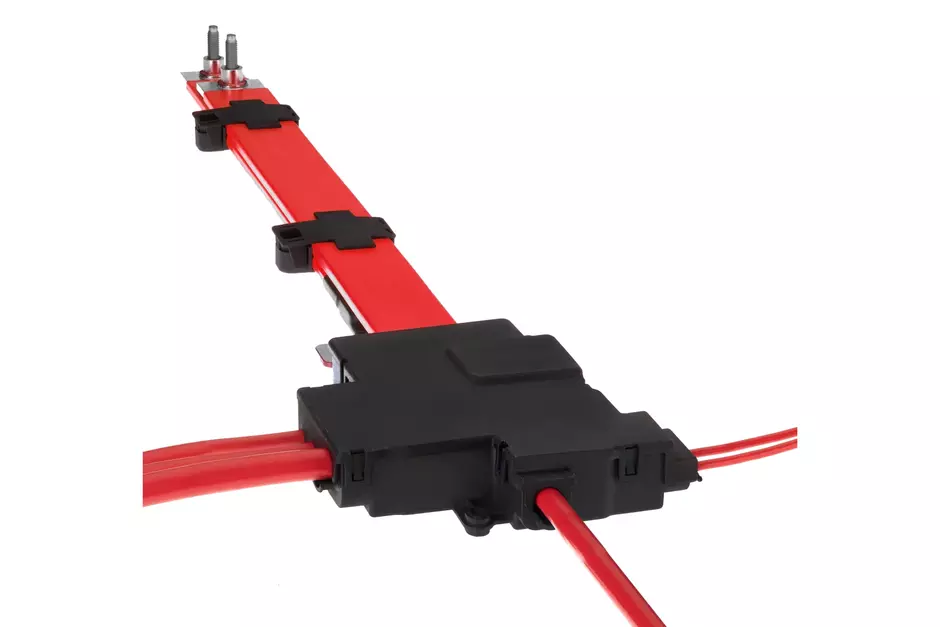

Current and future high-voltage on-board power supply systems require reliable, robust and safe power distribution due to their ever-increasing complexity. The use of high-voltage splices and high-voltage power distributors to reduce possible sources of error and thus to optimize weight, installation space and EMC is a key to success in such high-voltage architectures. LEONI uses single and multi-core cables with low contact resistances for EMC shielding and for high-voltage connections. With one input and two outputs, the LEONI Y-splice in hybrid and electric vehicles, for example, enables direct power supply to the auxiliary units. This component is small, lightweight and cost-effective and enables efficient expansion of the high-voltage network.